|

During a fender pile replacement project for Pier 7 in 2010, elevated PCBs, Hg, and other contaminants was found adjacent to and under Pier 7 (click here to view figure). Based on these findings, the Navy undertook laboratory treatability studies to evaluate an in situ treatment method using a reactive amendment. The project has been funded by the ESTCP program since 2011, with additional support by the Shipyard, NAVFAC NW, and NESDI. Following a successful laboratory evaluation, the field demonstration was initiated in August 2012 as a remedial action under the CERCLA ROD for OU B Marine.

Treatability Studies

The Pier 7 (BNC) sediment had a solids content of 33.7%, an initial total organic carbon concentration (TOC) of 2.4 – 3.1%, and consisted of 58.2% silt and clay sized particles. Treatability studies included testing the AquaBlok® formulation with site sediments to create a final measured sediment TOC concentration of 6.6%. The carbon addition from AquaBlok® was approximately 4.2%, which increased the indigenous sediment concentrations by a factor of 2.75 consistent with previously published target applications of AC.

Ex situ studies included chemical analyses of treated and untreated sediments, toxicity testing of the AquaBlok® formulation, tissue analyses from those bioassays, and laboratory evaluation of Sediment Profile Imaging as a tool to confirm post-placement presence of the activated carbon (click here to view Treatability Study).

Engineering Specifications and Contracting

The engineering design, specifications and contract oversight were done by Dalton, Olmsted and Fuglevand.The construction contractor was Envirocon Corporation, with the physical placement of material done by Quigg Brothers. The design specifications prepared by DOF are linked below.

The test area required placement in an open-water area (click here to view figure)

, and an under-pier area

(click here to view figure)

. The DOF design specifications required the placement of 2 inches of AquaBlok® across both areas, but let the contractors develop the method for placing the material across the open and under-pier areas (click here to view specifications).

Placement Methods

Placement was initiated on October 15, 2012. A description of the placement process is briefly described below; the summary report can viewed here. (click here to view DOF Summary Report). To take advantage of the low tides for under-dock placement the contractor worked 12 hr shifts through the nights of October 16-17. The AC was placed in both open berthing and under pier areas from the tug-operated, moored barge that contained the staged product packaged in the “Super Sacks,” a backhoe loader that moved each bag to a hopper feeder, and a truck-mounted conveyor belt-type (telebelt) broadcast conveyor system

(click here to view figure)

. The broadcast application obtained a rapid, relatively uniform placement of about 143 tons (130 metric tons) of product over the target area. The equipment was able to place the product both in the open access berthing area and under the pier by accessing the under pier areas between existing pilings during low tide. Once the barge was moored in the desired position, distribution of the product occurred relatively quickly, resulting in cycle-time of about 3 min/sack to distribute the product. A video link showing the placement methods is provided above.

On the morning of October 19, 2012 Navy divers were on site to observe placement of the final two sacks during daylight hours. Diver observations of product delivery showed that the small pebbles were resistant to the current velocities and sank slowly to the bottom settling on the existing bottom substrate, without any untoward impact to sea life on the bottom, such as sea anemones, sea stars, crabs, and flat fish. No turbidity plumes associated with the placement were observed. A video link showing the Aquablok+PAC falling through the water column is provided above.

Diver surveys, sediment cores, and SPI camera monitoring of the placement area conducted on October 30-31, 2012 showed that the PAC covering had released from the aggregate, as the light-colored aggregate was plainly visible on the seafloor. Initial observations indicated that the amendment was placed effectively over the target area; however variation in thickness was observed and there was some overspray or drift of the amendment slightly beyond the edge of the target area. A video link showing the post placement diver survey is provided above.

Performance Monitoring

Pre-placement and post-placement monitoring included Sediment Profile Imaging, bulk sediment chemistry, passive sampling of PCBs, bioassays, and in situ monitoring using the SeaRing System (ESTCP ER-201130).

At the time of this posting the monitoring is on-going. Interim monitoring reports can be found at the ESTCP Project website. Additional publications on the interim results are given in the references section. The final monitoring for the project occurred in July 2015. A final report will be posted on the ESTCP web site in 2016.

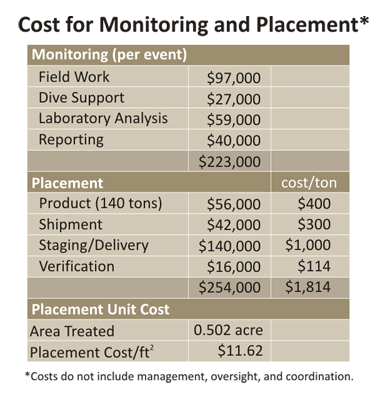

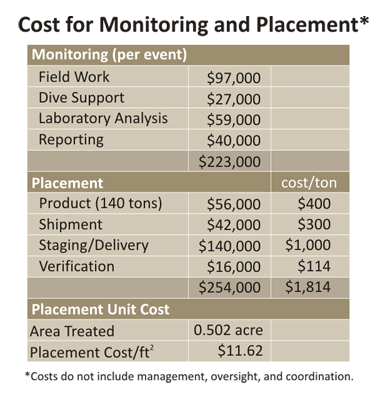

Costs

An interim cost assessment prepared by the project team is presented below. A final cost assessment will be included in the 2016 Final Report.

|