|

This was intended to limit dust created below the pier deck. While this worked for the AquaBlock + PAC™, the under-dock dust created by aerially broadcasting the SediMite™ created a hazardous (potentially explosive) condition. Placement was adjusted so that the under-deck crew placed material by directing the hose under-water.

A two person, under-deck crew worked off small, 4 foot by 8 foot work floats to place the material conveyed from the on-deck hopper. The cycle time for each of the 100 ft2 cells was approximately 10 minutes.

Vortex Spreader

Aggregate-AC (SediMite™) was placed using commercially-available vortex aquatic spreaders. Vortex spreaders are commonly used to apply agricultural fertilizers, weed control products, and a host of granular or pelletized products. These systems typically are two parts: a hopper and a blower system. The modular systems adapted for SediMite™ broadcasting included a 250-pound capacity polyethylene inductor hopper and a 2-stroke gasoline-powered blower unit. SediMite™ pellets were distributed by loading the pellets into the hopper, from which an electric articulating valve releases the pellets from the bottom of the hopper and into a manifold. The pellets are then blown from the manifold and through tubing that and aimed at the target of application. Case studies where this tool was used include Lower Canal Creek (MD), Baily Creek (VA), and Mirror Lake (DE) projects. Two videos show the loading, and use of the Vortex system for spreading the SediMite™ are available at the Baily Creek case study web page (click here to see the videos).

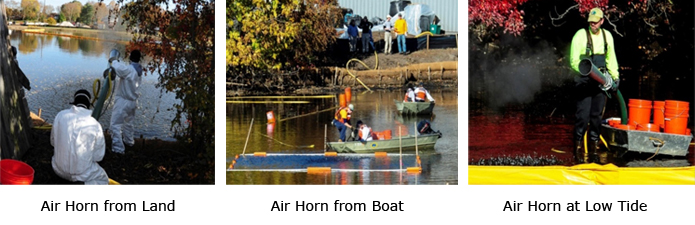

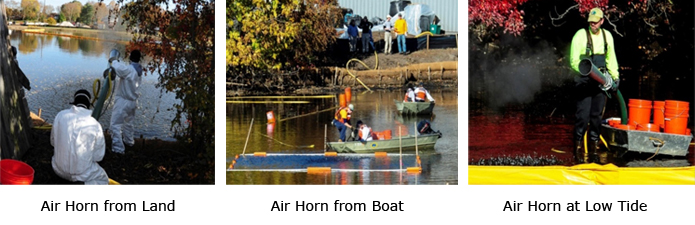

Induction Air Horn

A custom-built induction air horn was used to place aggregate-AC (as SediMite™) at Mirror Lake (DE). The pelletized PAC hopper was a simple 5 gallon bucket coupled to a compressed air system able to draw and project the pellets. The air horn was able to distribute the active carbon with an approximate range of 15 feet to 20 feet. The induction air horns were used on land and in the boats to spread the material along the banks of the lake as well as in the areas which were not accessible with the tele-belt (e,g. under overhanging trees). Transect lines and 20 foot by 20 foot grids were used to mark the application areas. Induction air horns were able to apply approximately 3-4 tons of product within an 8 hour work day

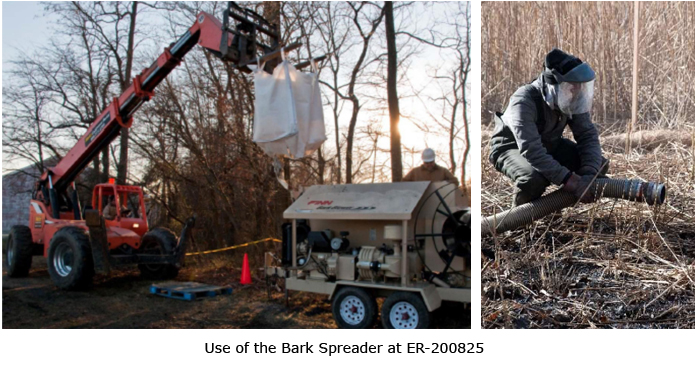

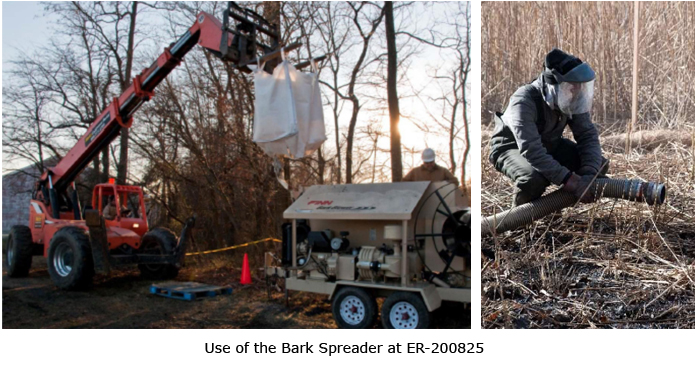

Bark Spreader

A commercially-available bark blower was adapted to broadcast approximately 26 tons of aggregate-AC (AquaBlok+PAC™) at the Canal Creek, MD site under ESTCP project ER-200825. The aggregate-AC was delivered in 1.25 ton super-sacks on pallets and a forklift was used to lift the super-sacks above the receiving hopper of the bark-blower, where they were subsequently emptied. Each of the test plots received approximately 3.3 tons of AquaBlok+PAC™ (approximately 6,550 pounds), but at each of the plots it was necessary to manually (hand) spread an additional 300 pounds of AquaBlok® via five gallon buckets achieve the target AC mass-loading.

Hydro-seeder

A commercially-available hydro-seeder was also adapted to broadcast particulate activated carbon (PAC) at the Canal Creek, MD site under ESTCP project ER-200825. PAC was spread by making a slurry in 750 gallon tank coupled to the hydro-seeder. The slurry tank was equipped with a mechanical agitators and re-circulating pumps that function to mix and keep the solids in suspension. Hydro-seeders range in size from small trailer mounted units to large truck mounted units; for this project a trailer-mounted spreader was used. Six hundred pounds of PAC and approximately 180 to 200 gallons of water (total weight of approximately 1,500 to 1,700 pounds) were loaded into the tank of the hydro-seeder to form a 35-40% slurry by mass. The hydro-seeder agitator was then used to mix the slurry, and approximately half of the mixture was pumped to each plot. An advantage of the hydro-seeing system is that the AC could be spread at hose lengths 300 - 500 feet from the pump. The application process was conducted in approximately 15 minutes for each plot, during which time an even coating of the slurry was applied over the entire plot. The application rate of the slurry was limited by the amount of water that can be applied to the wetland soils before the slurry was no longer adsorbed and began to flow off the test plot. Depending on the saturation and hydraulic conductivity of the soil, multiple applications were necessary to achieve the desired mass application rate.

|