|

ARTICULATING CONVEYOR

Telescoping-articulating conveyor (tele-belt) have been adapted for application of aggregated activated carbon (e.g., SediMite, Aqua-Gate+) for projects featured in the Case Studies web page. Additional sites where a tele-belt conveyor as used include a pilot study on the Lower Columbia Slough, in Portland, OR (ODEQ, 2016), and a permeable active carbon cap installed at River Mile 10.9 on the Lower Passaic River (Hicks and Collins, 2017).

|

|

Site |

Contaminant |

Year Constructed |

Project summary |

Target AC |

Delivery Methods |

Project Web Link |

|

AC Projects Completed in North America |

||||||

|

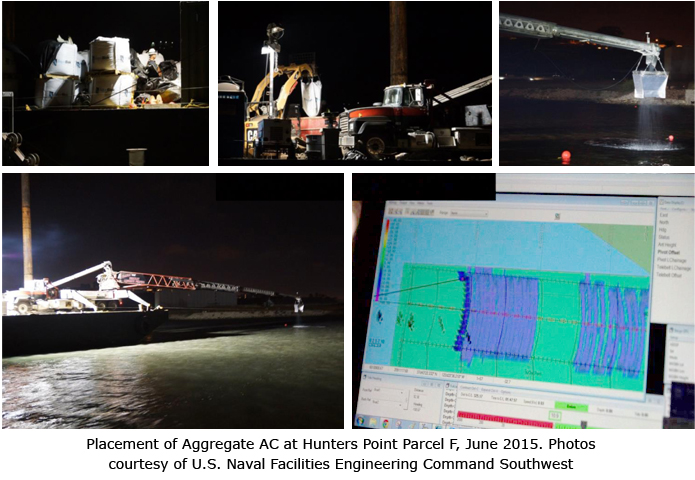

USN Hunters Point San Francisco Bay, CA |

PCBs & PAHs |

2015 |

1 acre pilot study that includes ca 0.5 acres of SediMite and 0.5 acres of AquaGate+PAC. |

4 - 6 % |

Telebelt ® |

|

|

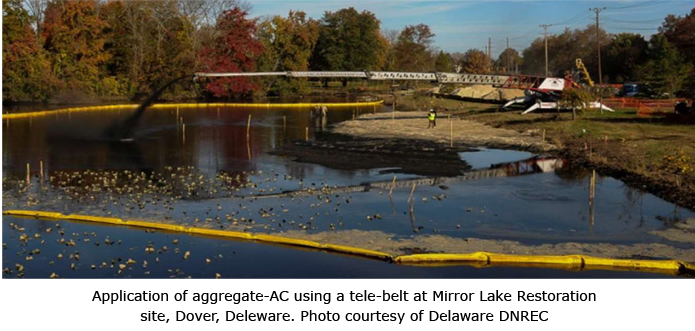

Mirror Lake Restoration Dover DE |

PCBs |

2014 |

Full-scale 4.9 acre remediation of lake and downstream with SediMite. |

5% |

Telebelt® in deeper areas of lake; induction air horn, vortex spreaders, and by hand in nearshore |

|

|

Puget Sound Naval Shipyard Bremerton, WA |

PCBs & mercury |

2012 |

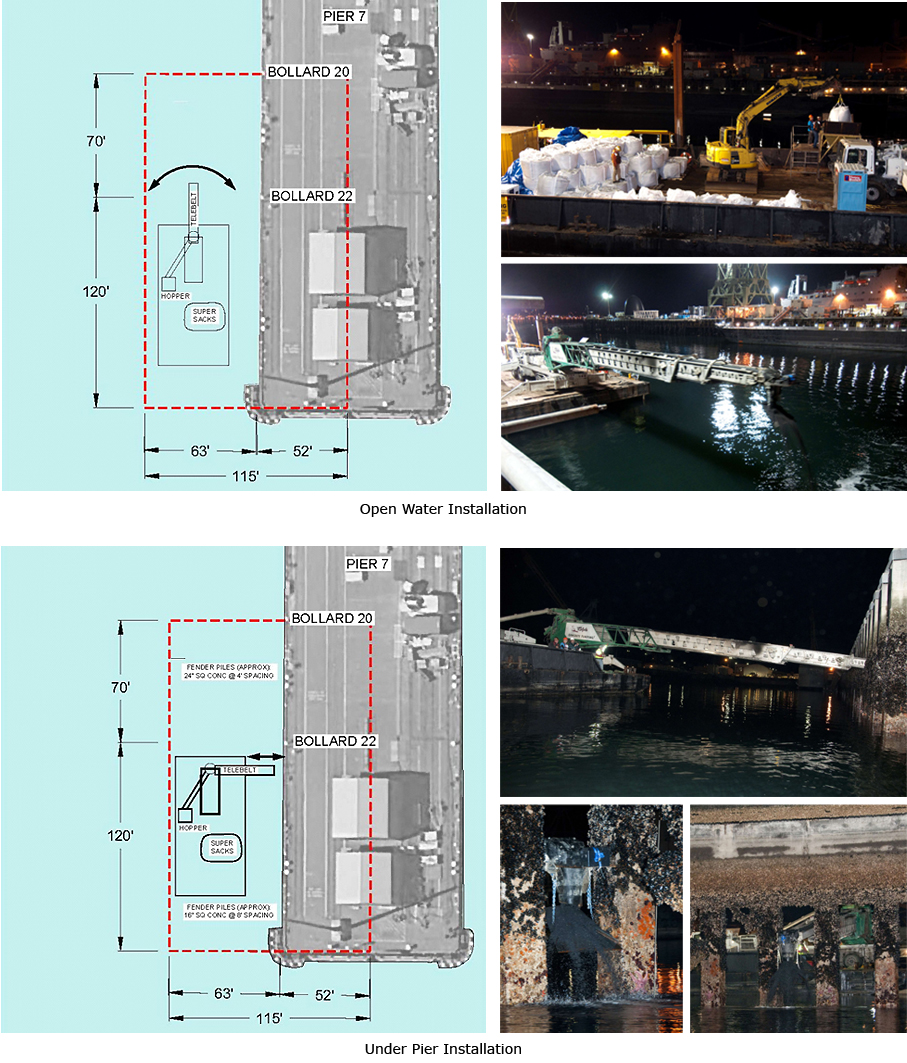

0.5 acre pilot study to evaluate the efficacy of AC application under an active Navy pier. Product was AquaGate+PAC. |

4% |

Telebelt ® over-water and under pier sections of the project. |

|

|

AC Placement at the PSNS |

|

|

|

|

The AquaBlock+PAC® was placed in both open berthing and under pier areas from a tug-operated, moored barge that contained the staged product packaged in "Super Sacks". A backhoe loader moved each bag to a hopper feeder, and a truck-mounted conveyor belt-type (Telebelt®) broadcast conveyor system. The broadcast application obtained a rapid, relatively uniform placement of about 143 tons (130 metric tons) of product over the target area. The equipment was able to place the product both in the open access berthing area and under the pier by accessing the under-pier areas between existing pilings during low tide. |

VIDEOSActivated Carbon Amendment Placement at PSNS October 2012Aggregate Activated Carbon Pellets in the Water Column at PSNS Diver Video Survey of Sea Floor Treated with Activated Carbon at PSNS |

|

Once the barge was moored in the desired position, distribution of the product occurred relatively quickly, resulting in cycle-time of about 3 min/sack to distribute the product. A video link showing the placement methods is provided above.

|